It’s no secret that the world needs new homes, and fast. The United Nations estimates that one point six billion people in the world lack adequate housing. America alone is facing a deficit of about four million housing units.

In Woodcreek North-Wimberley Springs, eight homes are being designed by the construction tech startup company ICON and the Bjarke Ingles Group.

Using huge robot arms controlled by a computer program, a high-strength concrete is layered in one-inch horizontal rows called “beads” to create walls according to a floor plan. It takes about 30 minutes to lay down each bead which hardens enough, roughly 15 minutes, to support the next layer before the next pass is made. Steel is added every tenth layer for strength. The

“As stewards of this planet, architects and designers need to do our part in reducing global carbon emissions to protect our world for future generations.”

– Architect Heather Gayle Holdridge homes can be built either on poured slab or bead foundations.

The huge upright robot arms seen at the building site on Peace Pipe in Woodcreek, runs on tracks along the foundation. Called “Vulcan,” the 9,500 pound printer allows ICON to build 12-foot, single-story homes. In 2026, ICON will roll out a new robot called “Phoenix.” Appearing more like a crane, it will allow the construction of multiple stories.

Each wall is made up of two layers of stacked beads separated by a space of several inches, called a two-bead wall system. Plumbing, electrical components and insulation are placed within the cavity. Overhead a steel truss will hold a seamed metal roof. Windows and doors will be installed traditionally once the walls fully cure. Once cured, walls can be painted and plastered.

The benefits are staggering. Not only is the process sustainable and environmentally conscious, the homes are energy efficient, durable and more resistant to natural disasters. In addition, building costs are greatly reduced. The construction process skips six entire trade steps. Fewer supplies are needed and the build time is reduced to ten days.

Lake | Flato associate and architect Heather Gayle Holdridge, who is the director of design performance for the firm, wrote in ARCHITECT magazine in 2023 that “Buildings are responsible for more greenhouse gas emissions than any other sector, including transportation and industry. This presents a great challenge to building professionals, but also a great opportunity, as we have the knowledge and skills necessary to reduce the carbon impacts of buildings. Climate change is one of the biggest threats of the 21st century and endangers national security, human health, food supply, natural ecosystems, and global economies. As stewards of this planet, architects and designers need to do our part in reducing global carbon emissions to protect our world for future generations.”

The homes have a three-hour fire rating, are resistant to mold, water and termites and are proven to withstand 250 mile-per-hour winds. ICON homes recently built in Tabasco, Mexico withstood an earthquake of a 7.4 magnitude without damage.

The resilient concrete wall system provides a thermal mass that slows heat transfer into and out of the home, allowing it to withstand cold snaps and heat waves more efficiently without increasing air conditioning or heating costs. Each home is also built to be solar ready.

ICON has developed a new wall material called Carbon X which will be unveiled in the Spring of 2025. When Carbon X is paired with ICON’s wall system and robotic construction methods, it is the lowest carbon residential building system to be used on a large scale.

In 2022, ICON built a Lake | Flato-designed home in east Austin called House Zero. The 2,400 square foot, three-bedroom home is a net zero home. Net zero homes are homes that produce as much energy as it consumes, resulting in a net zero energy bill.

House Zero has won multiple awards in the architecture and design communities, including being named one of TIME’s Best Inventions of 2022.

In Georgetown, ICON partnered this year with the homebuilding giant Lennar, to build 100 homes. It will be the country’s largest 3D printed community in the U.S.

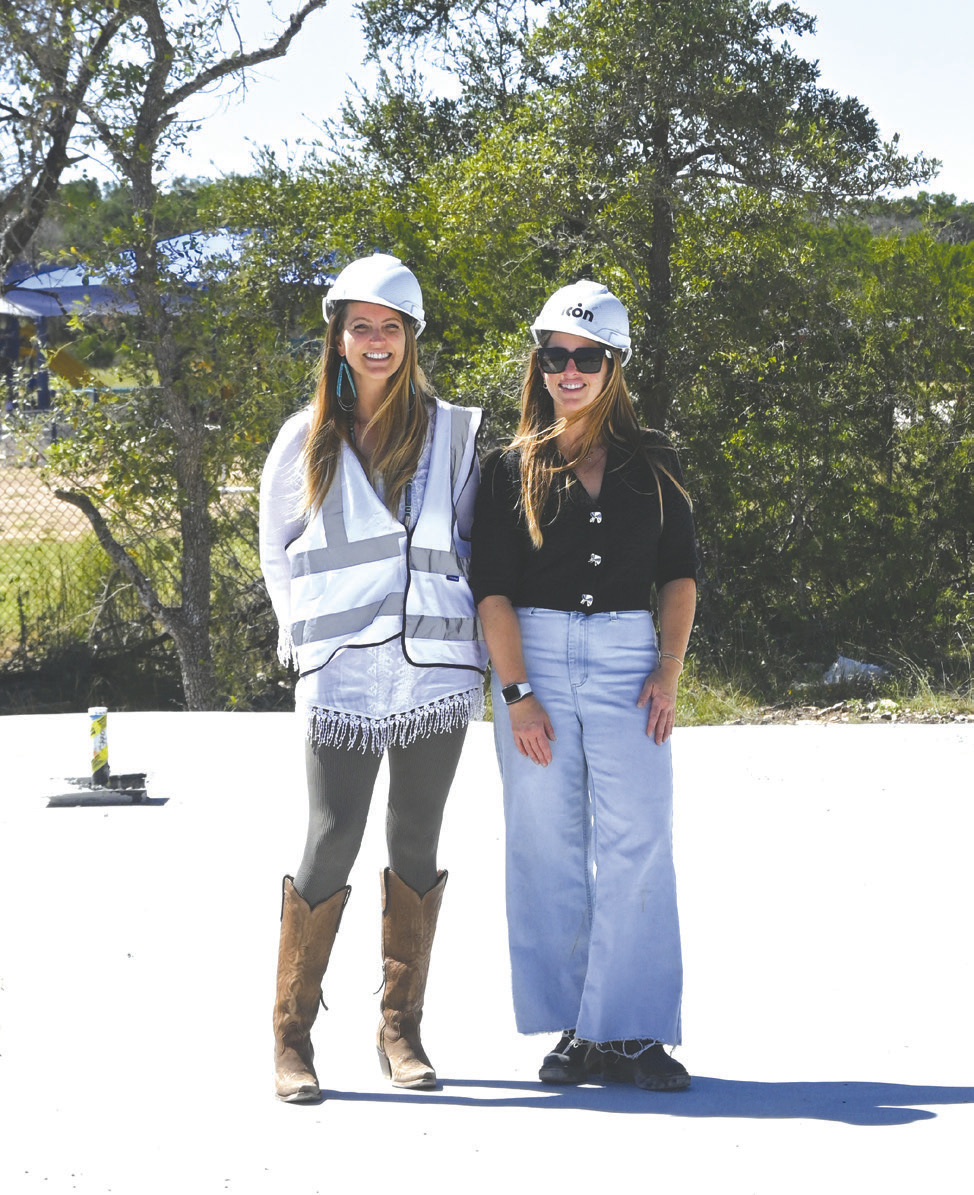

The eight single-family, four to five bedroom homes on Peace Pipe in Woodcreek start at $885,000 for a 2,920 square foot home. Sales are through realtor Nayeli King at 12 Rivers Realty, 13300 RR12. On hand to answer questions is Cara Caulkins, Senior Director, Public Relations and Events for ICON.